solder joint

The metallurgical bond connecting a component lead to a PCB pad.

Definition

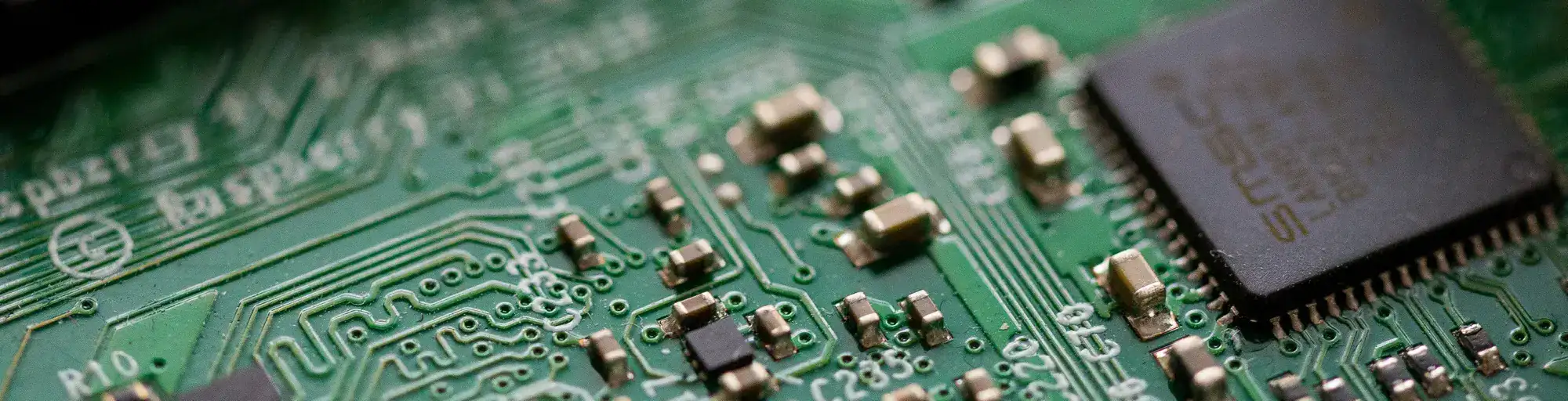

A solder joint is the metallurgical connection between a component terminal and a PCB pad. Joint reliability depends on: alloy choice (SAC305 for lead-free, Sn63Pb37 for leaded), pad design (size, finish), thermal profile, and mechanical stress. Good joints show smooth, shiny fillets with proper wetting. Defects include cold joints (insufficient heat), tombstoning (uneven heating), bridging (excess solder), and voids (trapped gas). Thermal cycling causes fatigue - larger joints with proper fillet geometry last longer. X-ray inspection reveals internal voids in BGA joints.